Industrial stretch wrapping lines are integrated systems that enable hygienic, safe, and aesthetically pleasing packaging of products in many sectors, primarily food and fast-moving consumer goods. These lines manage the entire packaging process automatically and controllably, from tanning and film wrapping to sealing and exit conveyor. They provide significant time and cost advantages compared to manual packaging methods in high-volume production facilities.

In modern production facilities, packaging is a critical stage not only for product protection but also for shelf life, logistical efficiency, and brand perception. An industrial stretch wrapping line minimizes product contact with external factors while offering standard and repeatable packaging quality. This ensures that products maintain their shape during shipping, storage, and at points of sale.

Industrial stretch wrapping line solutions adapt to high-volume production with operating speeds reaching tens of packages per minute. Adjustable speed options offer flexible use for different product types and production scenarios. This structure enables the line to operate continuously during sudden production increases or product changes.

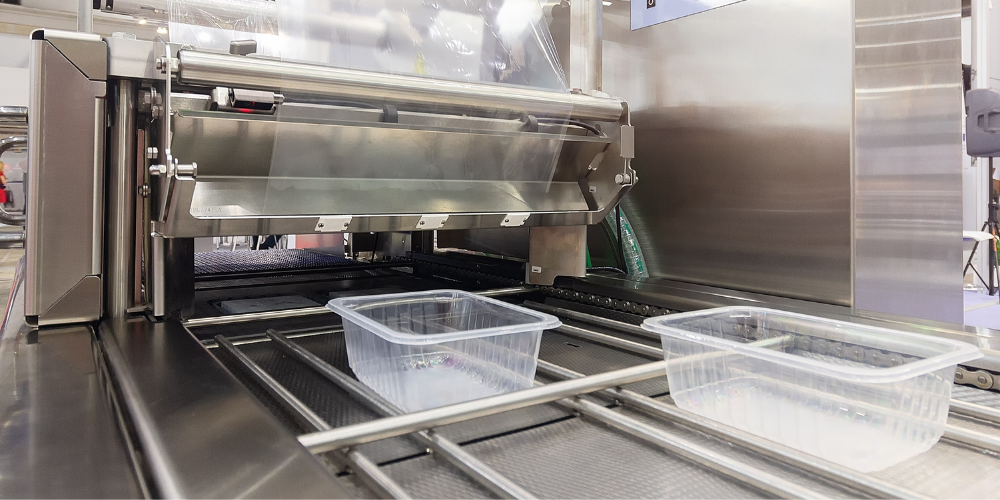

An industrial stretch wrapping line is designed to work with trays of varying sizes, shapes, and materials. Wide tray tolerances allow for the packaging of different products on the same line. This flexibility is a significant advantage, especially for multi-product manufacturing facilities, and reduces the need for additional machinery investment.

In stretch wrapping lines, film winding quality is crucial for both product presentation and cost control. Industrial stretch wrapping lines operate with systems that optimize film tension and winding geometry. This reduces film waste, standardizes packaging quality, and provides significant cost advantages in the long run.

In food production facilities, hygiene is one of the primary criteria in the design of packaging lines. The industrial stretch wrapping line meets hygiene requirements with its stainless steel body structures and easy-to-clean surfaces. The cornerless design and components that allow for quick cleaning support production continuity while minimizing food safety risks.

Today, energy consumption is a significant cost item for manufacturing facilities. The industrial stretch wrapping line operates with intelligent modes and optimized mechanical systems that reduce energy consumption during downtime. This approach both reduces environmental impact and lowers operating costs.

The industrial stretch wrapping line allows operators to easily manage the process thanks to user-friendly interfaces. Speed settings, product recipes, and line parameters can be quickly edited via touch screens. This reduces operator errors and supports production continuity.

An industrial stretch wrapping line is not just a packaging solution, but a strategic investment that directly impacts production efficiency and product quality. A properly configured line increases production speed while maintaining quality standards, providing businesses with a competitive advantage.