Benefits of Pallet Stretch Machine

Efficiency and Cost Effectiveness for Businesses

Pallet stretch wrapping machines, which are an indispensable part of logistics and storage processes today, provide vital benefits for businesses. This technology optimizes packaging processes, reduces costs and increases operational efficiency. In this blog post, the advantages of pallet stretch wrapping machines will be examined in detail, their areas of use and sectoral effects will be discussed. Comprehensive information will be provided on how businesses can benefit.

Function and Working Principle of Pallet Stretching Machine

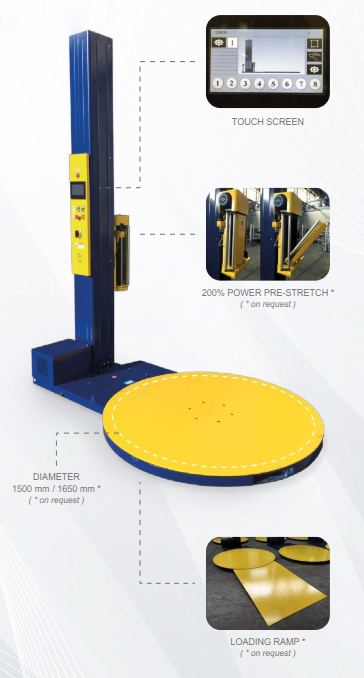

Pallet stretch wrapping machines are automatic or semi-automatic machines used to secure and protect products on pallets. These machines use a special packaging material called stretch film to tightly wrap products on pallets, thus preventing damage to products during transportation and storage. These machines, which have adjustable features according to pallet size and height, can effectively and quickly wrap pallets of different sizes. Modern stretch wrapping machines are equipped with programmable control panels, allowing businesses to customize the wrapping force and film wrapping according to their specific needs.

Different Pallet Stretching Machine Models and Prices

The market offers a wide range of pallet stretch wrapping machines. Automatic models, suitable for high-volume warehouses, provide significant labor savings, while manual models are ideal for businesses with lower volumes or low budgets. Stretch machine prices vary depending on the machine's capacity, speed, technology used, and additional features offered. Businesses should choose the model that best suits their needs by considering the balance between cost and performance. When doing price research, it is important to consider the savings the machine will provide in the long term.

Cost Advantages of Pallet Stretching Machines for Businesses

Pallet stretch wrapping machines are much more cost-effective than manual packaging methods. These machines minimize waste by using the required amount of stretch film, thus significantly saving on material costs. In addition, automatic stretch wrapping machines require less labor compared to manual labor, which leads to significant reductions in labor costs. Advanced sensor technologies and smart wrapping systems optimize film consumption and reduce energy consumption for businesses.

Increasing Operational Efficiency and Speed

Automatic pallet stretch wrapping machines dramatically reduce the wrapping time per pallet compared to manual operations. For businesses with high production volumes, this means significant time savings and faster product delivery. More efficient logistics operations provide a competitive advantage in the market. These machines, which consistently deliver high standards of wrapping quality, streamline workflows and minimize delays in production processes.

Product Safety and Protection

Pallet stretch wrapping machines protect products safely during transport and storage. Tightly wrapping products minimizes damage that may occur during transport. This protection is vital for fragile or delicate products. In addition, stretch film creates an effective barrier against water, dust and other external factors, thus increasing product protection and reducing the risk of contamination.

Sectoral Usage Areas and Applications

Pallet stretch wrapping machines are one of the equipment frequently used in the logistics and distribution sectors. They are also preferred in the food and beverage sector because these machines provide packaging that complies with food safety and hygiene standards. Pallet stretch wrapping machines, which are also ideal for production and manufacturing processes, ensure that products are effectively packaged and protected, increasing the productivity of businesses and maximizing customer satisfaction.

Understanding the Value of Long-Term Investing

Pallet stretch wrapping machines are an essential investment for modern businesses. They offer great advantages in terms of cost effectiveness, product protection and operational efficiency. By choosing the right pallet stretch wrapping machine model, businesses can both optimize their costs and maximize their operational efficiency. This investment has proven its value in terms of competitive advantage and customer satisfaction in the long term.